Sun Woodworking

Featured Classes

Make this lightweight Windsor style stick chair with a steam bent crest.

This is a great intro to chair making and for the more advanced a great way to explore design.

Utilize all my shop has to offer, machines, hand tools, steam box and kiln.

All parts will be made from rough lumber, the spindles can be made from the log using green woodworking techniques with a draw knife at the shaving bench. Parts will be finished with hand tools limiting sanding. You will leave with a good understanding of using and sharpening hand planes.

You will learn:

Processing wood from rough lumber and log.

Power tool and hand tool use

Hand tool set up and use

Saddling seats with hand tools

Green woodworking techniques

An understanding of how trees grow and how that relates to woodworking

3 days $600 maximum three students materials included.

This is the same lightweight Windsor style stick chair except it has a straight back that is carved instead of the steam bent curved crest.

The difference in the two classes is one back is curved using steam bending and the other is straight but embellished with 17th century inspired carvings made using dividers, marking gauge and a small set of gouges and V tool.

When materials allow, and they usually do, the crest is split from the log and carved, this is a fantastic experience in woodworking that allows the carvings to have a personality of their own. Some carving experience is helpful but not required, these are very basic carving techniques that can be used to embellish your future projects.

3 days $600

This can be combined with the steam bent crest class for a five day class making the two chairs.

$600 materials included

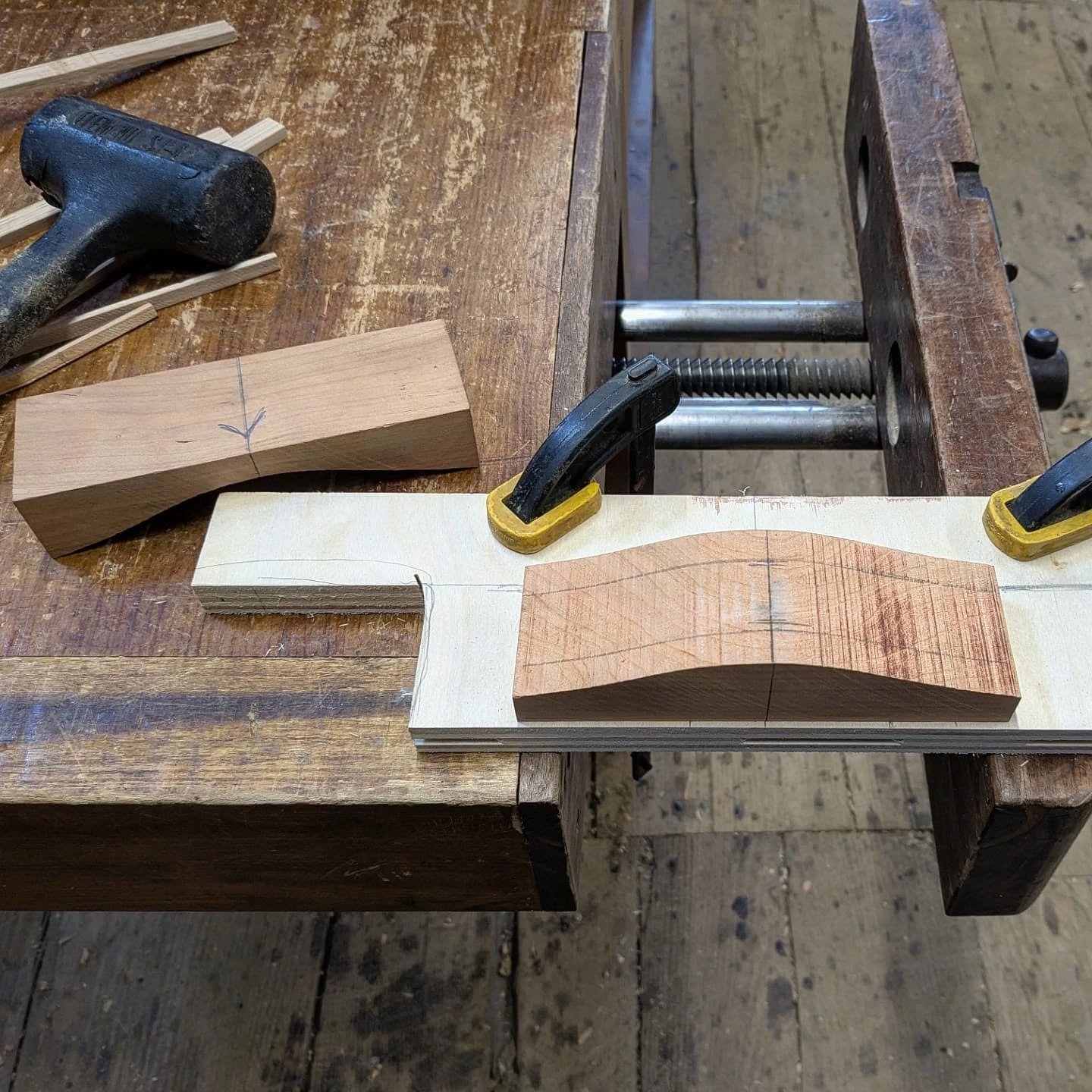

Make this steam bent wood carrier.

In this class we mix traditional steam bending sensibilities with some modern influences.

Bows are split from the log or sawn from green lumber. Steam bent over a form, we bend it all in one shot.

All parts are held together with sound joiner and you’ll make a copper rivet that keeps a split from occurring when fitting the legs into the bending form. Fun to make and very effective.

Post and rung joinery like in ladderback stick chairs this class has a lot of good techniques that will inspire you. Green woodworking and using the tools that compliment it like the draw knife, spokeshave, shave bench, along with a hewing hatchet and froe. Learn how to dry your own wood why and when its necessary.

Much to learn and discover about trees in this one.

3 days $600 maximum four students materials included

Hand tool workshop

This immersive one-day workshop focuses on hand planes, saws, and layout tools, empowering you to utilize these more affordable and easily accessible alternatives to power tools in your own workshop. Participants will gain a comprehensive understanding of the functionality and sharpening techniques of these essential tools.

A key aspect of the class will be addressing common challenges you may encounter and discovering practical solutions, along with general maintenance tips to ensure your tools remain enjoyable to use. We will explore essential setups including bench hooks, winding sticks, shooting boards, and alternative methods for securing your work on a bench without a vise. Additionally, you will learn how to properly prepare a rough-sawn board.

The course also covers effective use of layout tools, for accurately marking your workpiece.

This day can be catered to focus on tools or techniques you want to learn more about. Additional days can be added.

Contact me and let’s figure out your goals and direction.

$200 a day three people maximum materials and use of shop tools included.

3 leg stool, one of the most popular classes, the takeaway is so much more than this very usable stool. Mostly a machine tool class with hand tool clean up we dive deep into leg angles, sight lines and how they affect foot rest placement. We go through the design process starting with rough lumber usually this project starts from a slab of wood, not just boards, to get the seat or legs or both and where to start with layout. Hand cut tenons on the foot rest assure a custom fit. So much of this build applies to different aspects of woodworking, more than just making a stool.

Three days $600 materials included maximum two people

Make an English style shave horse or shave bench. If you really want to get into green woodworking especially chair making or making riven billets into squares or rounds a shave bench will make the process quick and efficient compared to the traditional work bench with a vise. Can also be helpful in spoon making and used as a bench around the shop or extra seating.

This is a mostly machine use class that is great to gain an understanding of processing wood from the rough. Leg to seat joinery is different front and back the reasons can be compared to counter stool design, like all the classes there is much more to consider than just making a shave bench. You will leave with a better understanding of woodworking with power and hand tools, design elements the use of different woods and an understanding of how trees grow.

Once completed we will put it to use going through the process of shaving chair parts.

3 days $750 materials included maximum two people

This kids woodworking class is for age 9+. We make a three leg stool. One class is a half day.

Workshops are held Thurs and Fri of each week 8:30-12:30. A parent or guardian must be present and can participate as much or as little as they want. The class is $150 and includes the $30 material fee, if more than one stool is to be made by a sibling or guardian an additional $30 materials fee is required. Shop space is limited max three students and guardians.

Woodworking machines are used as well as hand tools, saw, chisel, hand planes, students do as much or as little as they are comfortable with, I supervise and help through each step.

We talk about trees, how they grow and cell structure.

I’ll have a seat blank and three legs ready to go, we will lay out the seat and mark for drilling, cut the seat on the bandsaw, drill the leg mortises on the drill press. Carve a shallow contour in the seat top. Make the tenons on the legs using the lathe and assemble it, cut the tops off the legs flush with a chisel. Paint or finish is not included.

$150 per child plus $30 for each additional stool maximum three students and guardians must be present.

Sign Up For A Class

Interested in taking a class? email me at sunwoodworking@gmail.com and let me know which class you would like to take then we can talk through emails or over the phone and make a plan for the direction you want to go in. Classes are Monday through Friday 8:30 am to 4 pm. Please contact me for availability outside those days. Classes and workshops are in White Hall Maryland, in a rural inspiring setting.

I have been teaching woodworking classes from my shop for the last seven years and before that I taught “at risk youth” woodworking in Baltimore City. Before that I assisted and helped out teaching green woodworking and chairmaking at Country Workshops with Drew Langsner and also with John/Jennie Alexander in Baltimore going back as far as 1998.

Seven years is not that long and I am still working hard to fill classes. The goal is to be a reliable resource for woodworking instruction and have a class schedule that is set, and fills months out. I have put sheduals together, steam bending this month, three leg stool the month after and so on, more often than not no one signs up for the scheduled class but does reach out and say when is the next chair class for example. So we end up shedualling the class they want. This may seem unorthodox but please bear with me until things get going, as any small business does, I need you. As classes fill up and time frames shorten I will post availability and openings here and eventually a proper schedule.

There are hotels option within 30 minutes away. Hunt Valley MD to the south and Belair MD to the east and Shrewsbury and York PA to the north. These are the closet options with dining and conveniences. Airbnb and other options can be closer.

Woodworking Services

I do custom commercial pieces like this desk for The Wendy apartments in Arlington VA. I was fortunate to work with Sebastian Martorana an incredable stone carver and artist in Baltimore to make this desk for design firm Price Modern. Please contact me for your comercial and residential needs.

Nature Sacred commissions me to make benches for their quiet spaces. These go in landscaped areas in cities, preserving and creating green spaces, places to reflect and take a moment in difficult times.

As with every project I’ve attempted in my woodworking journey I set myself up to make many, it’s a good way to be profitable when margins are so tight like in woodworking. These benches are no different, my shop becomes a mini manufacturing plant.

If you need a production run or specific parts made please contact me.

I always have wood carriers for sale, they are a popular staple especially around the holidays.

Mass produced by me but still in keeping with their traditional lineage, green wood split from the tree and steam bent over a form I made, one by one. They are amazing to use incredibly lightweight for the amount of firewood they hold. I don’t hardly bend over any more getting wood, just lean on the handle with one hand and set wood in with the other hand, carry the whole thing in set it down and done. They are great for weeding the garden or keeping indoors holding quilts. My grandfather used one to take the news papers out for recycling.

They are $125 and can be mailed. If a business or store wants to carry them I sell lots of 10. Please email me for pricing.

Instagram Feed, this is the place to see what I am currently working on, past projects and classes.